Quality

We follow a high standard to maintain quality for all equipment that are manufactured.

Materials

All materials used in fabrication will be food grade. Where ever Stainless Steel is used will be food grade unless it is specified otherwise. This factor will be adhered in accordance with Indian Standard code IS 6913-1973/5.1. All tops will be fabricated out of 16 SWG SS in accordance with IS 1387-1967. All panels will be fabricated out of 20 SWG SS in accordance with IS 1387-1967. All uprights will be of 30mm Square and 16 SWG in accordance with IS 7138-1973. All cross support will be of 24 mm round/square weld pipes out of 20 SWG in accordance with IS 7138-1973. All frame structures will be out of 24 mm SS food grade square pipes out of 20 SWG in accordance with IS 7138-1973 Wall thickness of the pipe will vary from 1 to 1.5 mm depending up on the area of usage. Wall thickness of all pipes used as specified above is in confirmation with the Indian Standard code on specification for steel tubes and mentioned in Is code number IS 7138-1973 amendment no 1 of Nov 1975. All tubes/pipes will be welded as per the provisions of IS 6913-3.

Manufacturing All sinks will be fabricated out of 16 SWG SS AISI Gr 304 in accordance to the standards specified as per BIS standard code IS 771 part 2 of 1985. SS sinks will be provided with slope for water flow in accordance with IS 771/1995. Sunk in tops will be provided for all tops with Sinks. Sunk in Angle will be in accordance with the standard practice and will be 120d. All coved corners welded will be finished without dirt pockets if work tops are provided with Splash back it will be straight to sight as per the provisions of Is 7138-1973-7.1. The height of the Splash back will be 150 mm and a built-in angle of not more than 45d.

Components

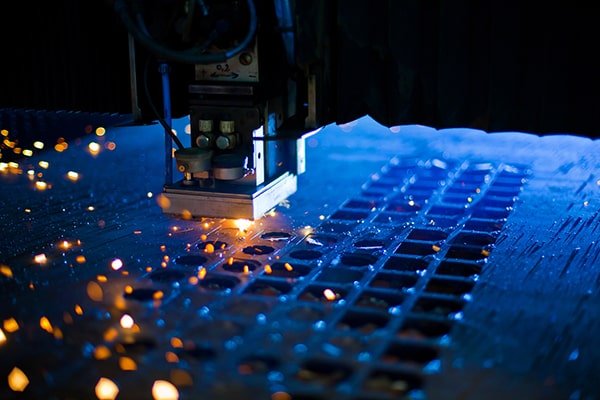

All bullet feet would be of Aluminum or Nylon. All pans and containers would be of GN standards and die pressed. Thickness of the pans could vary from .7 to .8 mm depending on the size of the container. All pans and containers lids would be of GN standards and die pressed. Thickness of the pans could vary from .6 to .7 mm depending on the size of the container. All Electrical components would be ISI marked and in accordance with the specifications it implies. SS components of intricate shape would be laser cut. All hangers would be out of 14 SWG. All SS sinks will be provided with the standard drain coupling of 1.5 inches. Fabrication of all sinks will be as per the provisions of IS code 8718:197. All Electrical Circuit will be having isolated circuits with MCB/ELCB. All heavy electrical connection (above 1.5KW) will be provided with heavy gauge FR wires. Where ever Mild Steel is used a three-layer corrosion protection will be applied. All screws and fasteners used will be IS standards mm thread.

Accuracy

A fabrication accuracy of +/-5 mm will be adhered to as per the provisions of IS 7138/4.2 and 4.1 Tolerance of the Outer dimensions of tubes and uprights will be within the permissible deviation of 2%. Permissible deviations in wall thickness 8%. Straightness: All tubes and sheets fabricated areas will be straight to sight as per the provisions of IS 7138-1973.

Fabrication

Only TIG welding will be used for fabrication welding of SS sheets. The welding procedure will be in accordance with the Indian WElde4rs Manual. The inert gas in use will a gas combination of 98% AR and 2% O2. Filler Rod of AISI 304 L will be used for TIG welding All TIG welded areas will be finished to a minimum RA value of 20 as per IS 6913:197. The sheet metal is fabricated using the latest - Laser CNC cutting, welding and cleaning machines to obtain high quality output. The heated chamber will be insulated and will be wire brush finished for energy saving. Hydro forming will be used to form the edges in place of conventional impact bending.

Finishing

Five Stage finishing Process would be adopted for all Stainless-Steel Surfaces. Stages 1: Emery grit 60, stage 2: Fine Emery grit 120, Stage 3: Flap, Stage 4: Wire, Stage 5: Final. All Tubes shall be clean and free from Scales, cracks IS code 7138 5.1 clauses. Cut ends of the tubes shall be free from burr IS code 7138 5.1 clauses. All SS surfaces will be free from laminations IS code 7138 5.11 clauses. Surface Finish on all surfaces would be in accordance with the IS codes 6913-1973 Clause 8.5 roughness of any weld bead would be less than Ra 16. Finished tubes and up rights would be straight and have smooth ends free from burrs. They shall be free from injurious defects and shall have a work manlike finish as per the provisions of IS code 6913-1973-8.1. All Surface finish adherence would be done in accordance with the IS: 3073-1967 clauses 4.1/4.2/5.1/4.7.

Packing

Each and every Equipment would be protected before transportation to avoid scratches and distortion to maintain fabrication standards. Equipment would be transported only in open deck transport.